Select a School...

Select a School

- Cherry Park Elementary

- Central Child Development Center

- Ebenezer Avenue Elementary School

- Ebinport Elementary School

- Independence Elementary School

- India Hook Elementary School

- Lesslie Elementary School

- Mount Gallant Elementary School

- Mount Holly Elementary School

- Northside Elementary School of the Arts

- Oakdale Elementary School

- Old Pointe Elementary School

- Richmond Drive Elementary School

- Sunset Park CAS

- York Road Elementary School

- Castle Heights Middle School

- Dutchman Creek Middle School

- Rawlinson Road Middle School

- Saluda Trail Middle School

- Sullivan Middle School

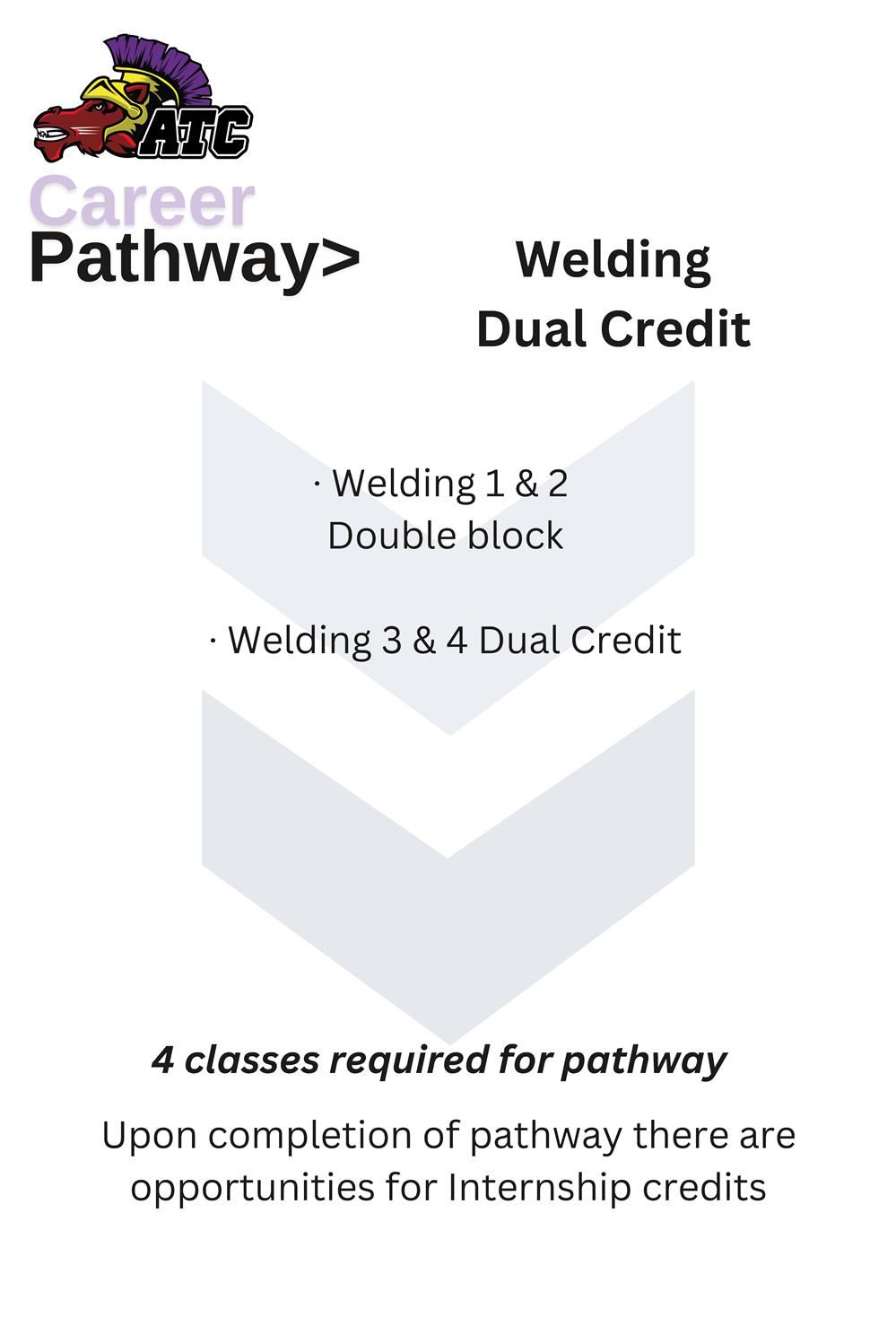

- Applied Technology Center

- Alternative Programs

- Northwestern High School

- Rock Hill High School

- South Pointe High School

- Adult Education

- Virtual Academy

- RHS Enrollment & Verification

- Program Options